Customers use the devices to assure their manufacturing quality or to support their product development and use the measurements in test laboratories or production lines.

The test devices are based on patented testing methods and are used for reproducible measurements of the cutting properties of particularly sharp cutting edges. Meaningful characteristic values for evaluating the cutting properties and the

quality of the cutting edge are determined on the basis of cutting force measurements.

With the SRF tester, cutting ability characteristics of blades - especially razor blades and cutter knives - are determined in a point with the thread cut. When using the thread-cutting method, a hair-like test medium is repeatedly

cut through in a pressure cut and the blade is destructively tested. With each cut, a force-displacement curve is measured under previously determined test conditions. The respective maximum of the curve is evaluated as the maximum

cutting force per cut.

Detailed view of measurement data

By repeatedly cutting the test medium and evaluating the maximum force per cut, a wear curve is formed.

Detailed view of wear curve

The following characteristics are recorded with the repeated force-displacement measurements until the end of the edges service life.

Characteristics of the test method

- Initial cutting ability or sharpness of the blade

- Abrasion on the coating of the blade

- Wear increase and characteristics of the blade

- Number of cuts up to the specified end of service life

- Number of cuts and maximum force at failure of the blade

- Characteristic values for cutting ability and edge retention

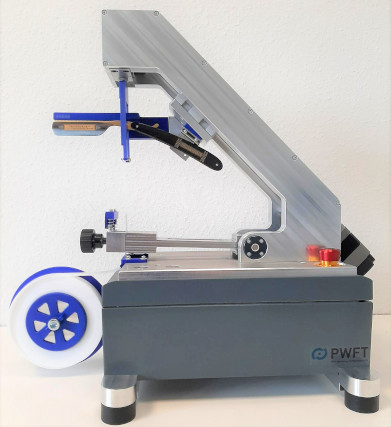

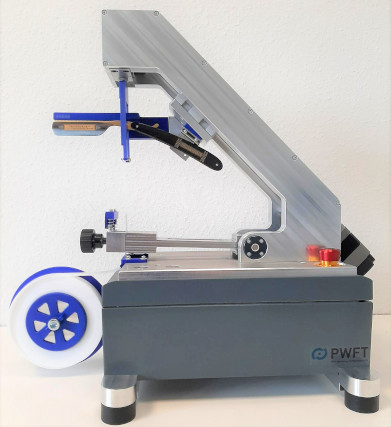

The SRMB tester is used to test the cutting ability and freedom of damage of blades - especially razors - over its entire cutting length in a tape cutting method. When using the tape cutting method, a thin foil is cut through in a

longitudinal cut (combination of tension and compression cut) and the required cutting force is measured. When using the patented measuring method, the cutting ability is recorded over the complete cutting length. The cut does not

affect the sharpness of the cutting edge, i.e. it is non-destructive and is used to ensure the manufacturing quality at the end of the production process. Since damage or burrs on the blade can be reliably detected on the basis of the

force curve, the test is ideally suited for continuous assurance of the manufacturing quality.

Detailed view of razor test

Features of the test method

- Longitudinal foil cut along the entire length of the blade

- Non-destructive test methods

- Measurement of cutting edge sharpness over the entire blade length

- Reliable identification of damage and defects in the manufacturing process (burrs, chipping or notches)

- Checking for correct cutting edge