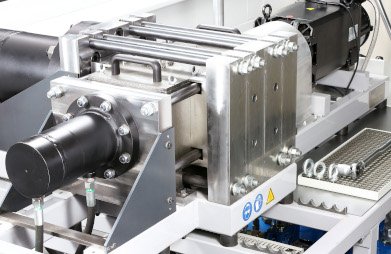

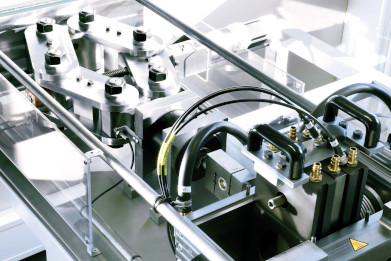

PWFT develops and builds test benches for functional and continuous load testing of industrial rolling bearings, also for special applications, including commissioning and service.

The rolling bearing test systems are used to test specific properties of rolling bearings. Popular customer requirements are the achievable life expectancy of the rolling bearings under specified load profiles and the functionality of the seals of sealed bearings under adverse operating conditions. Especially if there is no field experience with the product, the customer often insists on proof of the relevant product characteristics before a series release. For this purpose, the rolling bearings are tested under mutually agreed conditions adapted to the operating behaviour and, as far as possible, checked with quantitative characteristic values. For this purpose, PWFT develops test benches in accordance with the customer's specification, which are designed for a specific application. Independently of this, we also implement the standardised test processes of DIN 51819.

In the test bench, the rolling bearings are tested in controlled laboratory tests under realistic operating conditions. Depending on the test bench design, important parameters such as drive power and torque, speed, lubrication and contamination can be varied during the test. The manipulated variables for loading the bearings are continuously monitored and recorded, as are temperature and vibrations.

The test data obtained is used for the following purposes:

You are interested in our products and our solutions?

You are looking for an individual and holistic solution strategy?

Would you like a non-binding consultation?

We are happy to take the time for you and look forward to your inquiry by E-Mail or call us under +49 2137-9385315.

I look forward to talking to you!

Yours Marius Nahler

Managing director PWFT GmbH