Development of construction and test equipment

Customized measuring and testing of your product characteristics - from the measuring method to the testing device

PWFT develops application-related solutions for specific measuring and testing tasks and implements them in practice-oriented test equipment.

Our services

|

|

Development of test methods

|

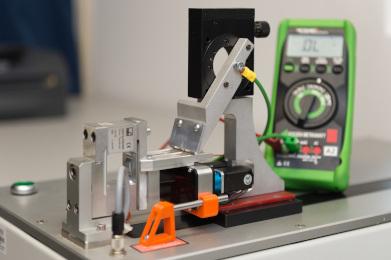

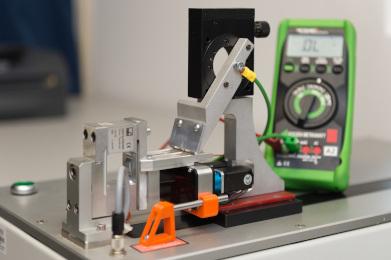

You want to test specific features or functions of your product for which there are no tests? Then our cooperation starts with developing and validating a suitable test method for you! We specialise in measurement and testing tasks for

which no standardised testing solutions are available. This is especially often the case when the requirements for product testing go beyond quality assurance of the manufacturing process and are oriented towards the behaviour of the

products. Very often, we first test and validate our measurement methods with pragmatic test set-ups. In this way, we lay an effective foundation for the subsequent targeted development of test equipment.

|

|

Development of concepts for test equipment

|

In the second step, the test method is implemented in a test device in accordance with set requirements. The competence to implement the mechatronic products is available in-house. PWFT develops concept alternatives that are

prioritised and approved by the customer. In doing so, our engineers proceed systematically and draw on knowledge and experience in the application of measurement and sensor technology.

|

|

Mechanical and electrical construction

|

Test equipment is generally a mechatronic product and requires corresponding competence in design and development. Holistic, interdisciplinary thinking and a cooperative development atmosphere in the team are particularly important. We

offer the necessary mechatronic competence and have a creative development team at our disposal.

|

|

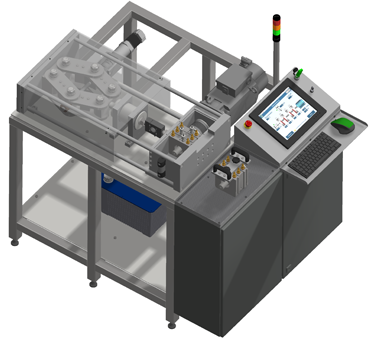

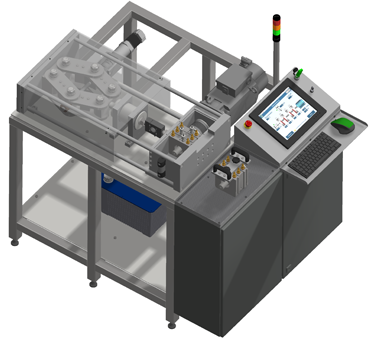

Construction of mechatronic devices and components

|

With us you get everything from a single source! We assemble all developed mechatronic test equipment and components ourselves! We assemble mechanical components, sensors, control cabinets, cabling and the electronics. Here too, we

always think holistically and functionally. The construction of more complex test devices is flanked by the decoupling of prototypical functional units, as far as this makes sense.

We also develop the software functions and implement the integration of all processes and evaluations ourselves. The programming know-how is available and the operating and evaluation software of the devices is developed the designated

application in mind. In this way, we ensure that you will see yourself represented in your product in the best possible way.

|

|

Testing and commissioning of the test equipment

|

The developed test equipment and any functional prototypes are put into operation in our company and tested with validation and verification tests. The test scenarios are planned in the concept phase in accordance with requirements

determined in coordination with you, our customers. The aim is to implement your requirements in the best possible way.

|

|

Implementation at the customer

|

We implement our testing devices in your company and ensure that all necessary measures are taken to guarantee a smooth start-up of the new testing processes. For this purpose, we document the handling of the testing process as well as

the software and evaluation functions. We train your staff and accompany the introduction phase according to your wishes and requirements!

We offer you an after-sales service for our devices and take care of the maintenance of them, the supply of consumables and possible expansion wishes. Thanks to our own high level of expertise, we can provide you with comprehensive

advice and support.

From consulting to conception to the development of a test bench - this is how we proceed

The starting point is usually the customer's wish to test a specific feature or function of their product. The requirements for product tests and measurements often go beyond the quality assurance of a manufacturing process and are

oriented towards the application behaviour of the products. This results in requirements for which no standardised test solutions are available. For these cases in particular, PWFT offers you support tailored to your needs. If no suitable

test method is yet available for the specific product feature or product property, PWFT offers you the development of a measurement or test method. In doing so, PWFT engineers proceed systematically and draw on knowledge and experience in

the application of measurement technology and sensor technology. In the second step, the test method is implemented in a test device according to requirements. The competence to implement the mostly mechatronic products is available

in-house. PWFT develops concept alternatives which are prioritised and approved by the customer. The PWFT team then carries out the mechanical and electrical design as well as the software development. The test device is built,

commissioned and tested in cooperation with the customer. PWFT accompanies the implementation of the test device at the customer's premises and offers an after-sales service.