TESTING DEVICES FOR THE SHARPNESS TESTING OF KNIVES

PWFT testers for the measurement of cutting edge sharpness

PWFT has developed a range of its own testing devices for testing the sharpness of knives, with which different applications and cutting patterns are depicted.

The measuring devices are developed and built in-house, of which several are patented. They can be used in the laboratory environment, but can also be integrated into an existing manufacturing cell for in-process quality testing. With the

non-destructive tests, the manufacturing quality can be determined and verified directly on the end product. The cutting properties of the finished blade are not affected.

All measuring and testing devices are equipped with high-resolution and calibrated measuring equipment. The measurement data generated is graphically visualised and stored in a database for further processing.

OUR PRODUCTS

|

|

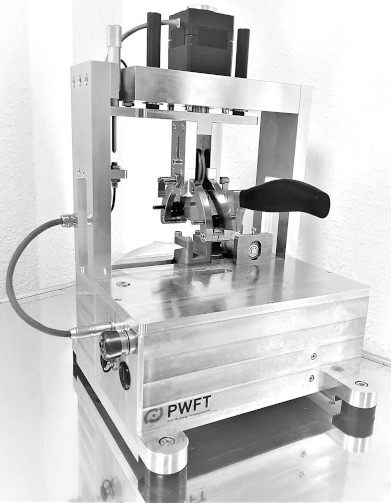

MasterCut-Z - Ensuring manufacturing quality in production

|

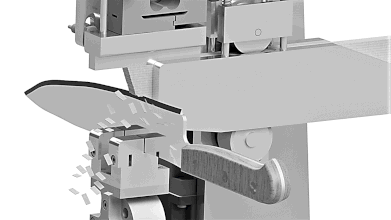

With the MasterCutTest, production quality can be effectively and safely monitored at the end of the manufacturing process. The non-destructive tensile test method in which a band-shaped medium is cut with the MasterCut-Z test device

does not affect the sharpness of the blade, but reliably detects possible production defects such as insufficient sharpening, burrs or other damage. The tester measures the forces acting on the material being cut. Manufacturing

defects are identified from force-displacement or force-time curves along the entire cutting edge. An arrangement for maintaining constant pretension is patented. The blade can be guided by a robot or a linear axis.

Functional principle longitudinal foil cut

Product features

- Non-destructive, production-accompanying cutting ability testing of cutting goods by means of cutting force measurements

- Quality parameters - initial cutting ability (sharpness), absence of burrs and notches or other damage

- Areas of application - in the production environment or in the measuring laboratory

Advantages

- Non-destructive complete testing of the entire cutting edge

- Constant preload of the test medium over the entire cut

- Reproducible cutting force curves

- 100% or random sample testing

- Cost-effective test medium

- No costly storage and conditioning of the test medium

|

|

ProCut-Z - Non-destructive tensile cutting for the test laboratory

|

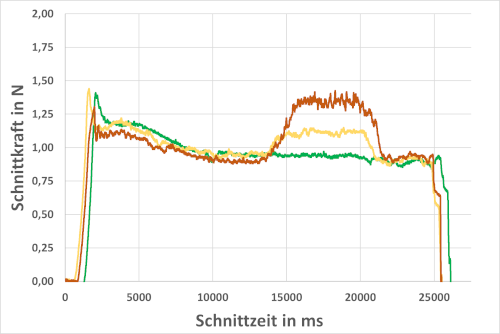

The ProCut-Z tester is designed for the test laboratory and reproduces the non-destructive tensile cutting tests through a band-shaped medium. The blade is moved with an integrated linear axis. Optionally, a test robot can be

connected. As with the MasterCut-Z, a constantly preloaded, band-shaped medium is separated. The force-displacement or force-time signal shows the cutting ability

over the entire cutting edges length. Extended evaluation options are

available for the measured data, which can be integrated into quality assurance processes or provide valuable information for the development process.

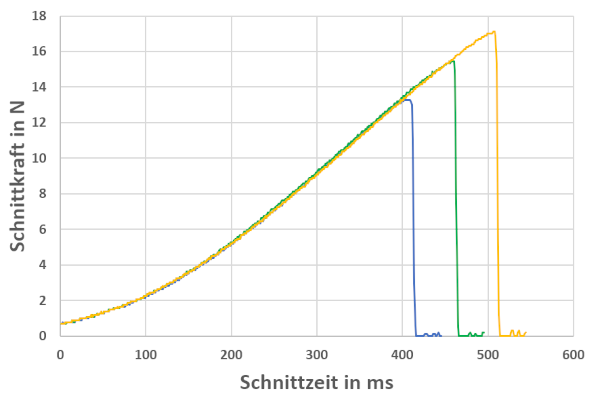

Force curve of a knife, determined with ProCut-Z

green: working sharp; orange: one stroke in the cutting ability test according to DIN 8442-5; red: : ten strokes in the cutting ability test according to DIN 8442-5

Product features

- Non-destructive cutting ability, testing of cutting goods by means of cutting force measurements in a longitudinal foil cut

- Quality parameters - cutting ability (sharpness), degree of wear, damage (burrs, notches, flattening of the bevel, break-outs)

- Areas of application - in the test laboratory or in the QA area

Advantages

- Non-destructive complete inspection of the entire cutting edge

- Constant preload of the test medium over the entire cut

- Reproducible cutting force curves

- Extended visualisation and analysis possibilities of the signal curves

- Cost-effective test medium

- No time-consuming storage and conditioning of the test medium

|

|

ProCut-D - Non-destructive pressure cut for the test laboratory

|

The ProCut-D is a test device for pressure cutting. The knife or blade is pressed into stretched foil or into a flexible test medium covered with foil. This process is used to simulate numerous typical cutting processes on cooked

products, such as the cutting of a tomato. The procedure is patented and is offered exclusively by PWFT. In particular, minimal differences in sharpness can be measured non-destructively. A cutting area of about 20 mm is tested with

each pressure cut.

Force curve of three knives with different grinding qualities, determined with ProCut-D

Product features

- Non-destructive cutting ability testing of cutting goods by means of cutting force measurements in a pressure cut

- Quality parameters - cutting ability (sharpness), degree of wear, flattening of bevels

- Areas of application - in the test laboratory or in the QA area

Advantages

- High sensitivity

- Analogy to numerous cutting processes

- Reproducible cutting forces

- Extended visualisation and analysis possibilities

- Cost-effective test medium

- No costly storage and conditioning of the test medium

|

|

EasyCut-Z - the test during resharpening

|

EasyCut-Z is built for the specialist cutlery trade and for artisan resharpeners. The device is compact, can stand on the counter and enables the demonstration of cutting edge sharpness. During resharpening, a before and after picture

of the cutting ability can be measured and demonstrated. The customer receives a quality certificate with cutting force curves of their knife. Here, too, the non-destructive longitudinal foil cut is used, which is also used in the

MasterCut-Z and the ProCut-Z.

EasyCut-Z with Display

Product features

- Non-destructive cutting ability testing of cutting products based on cutting force measurements in the longitudinal foil cut.

- Cutting force curves over the entire cutting length

- Quality parameters - cutting ability (sharpness), degree of wear, damage (burrs, notches, flattening of bevels, break-outs)

- Areas of application - in specialist shops or for resharpening companies to prove cutting edge sharpness and freedom from damage

Advantages

- Non-destructive complete inspection of the entire cutting edge

- Constant preload of the test medium over the entire cut

- Reproducible cutting force curves

- Quality certificate - cutting force curves as proof of quality for the customer

- Cost-effective test medium

- No costly storage and conditioning of the test medium

|

|

Cutting performance test according to DIN 8442-5

|

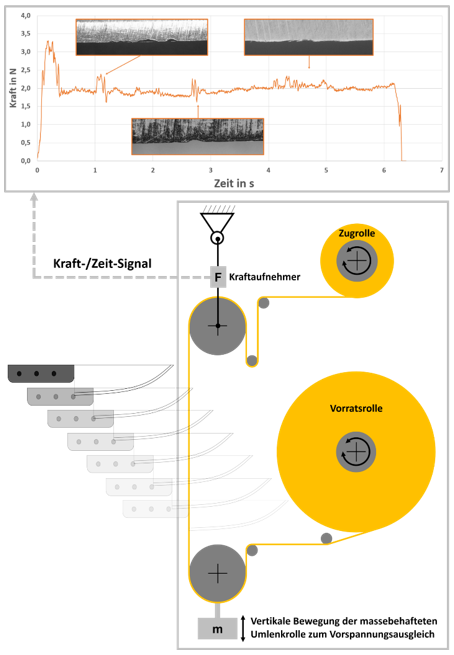

The cutting performance test is the most frequently used test method by knife manufacturers in industry and trade. Standardisation and years of use still make the cutting performance test indispensable in many companies. The cutting

performance test is a well-established quality assurance process and offers the option of comparing new data with historic data. Therefore, the disadvantages of the destructive test and the weak analogy to the actual usage behaviour

of the knives are often tolerated.

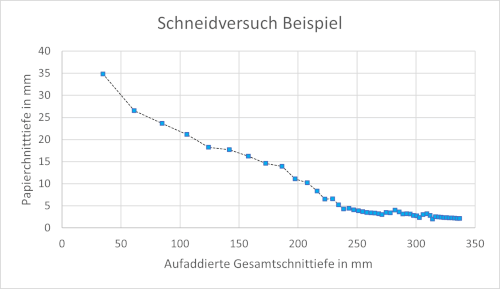

Exemplary measuring curve of the cutting performance test according to DIN 8442-5

Product features

- Destructive cutting ability and cutting edge retention testing of cutting goods based on cuts in an abrasive paper stack

- Quality parameters - cutting ability (ICP), cutting edge retention (TCP)

- Areas of application - random sample testing in the quality assurance of manufacturing companies

Advantages

- Standardised procedure

- Large amount of historical data as a basis for comparison

- Well-known and proven method of quality inspection

- Statement on initial cutting ability (sharpness) and cutting edge retention (tool life)